- Home

- Products

- Pouch Packaging Machinery

- Dual-Lane Rotary Premade Pouch Packaging Machine

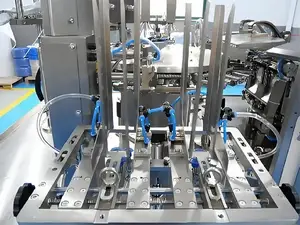

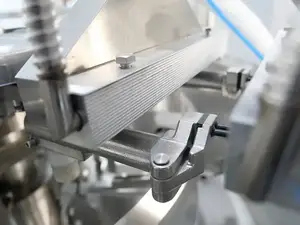

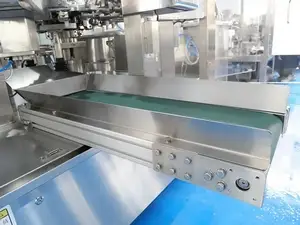

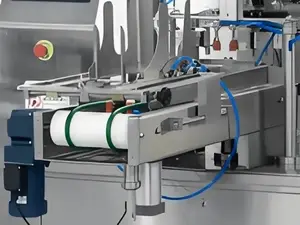

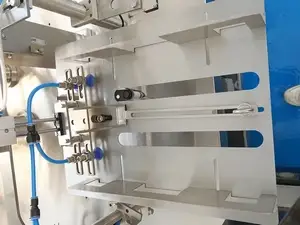

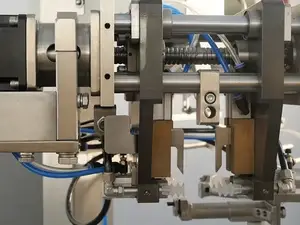

Automatic Dual-Lane Rotary Premade Pouch Packaging Machine

Rotary pouch filling and sealing machine for packaging granules, powders and liquids into two premade pouches at once

The WHD series dual-lane rotary premade pouch filling and sealing machine is designed for bags up to 170mm wide, offering a capacity twice that of the rotary model. It saves space and reduces the need for operators, making it ideal for packaging liquids, powders, and granules. It supports various pouch types, including flat bags, spout pouches, zipper bags, stand-up pouches, stand-up zipper pouches, shaped bags, and eight-side seal bags.

- Bag width

85 to 170mm

- Filling range

10 to 1000g

- Packaging speed

60 to 80 bags per minute

Request a Quote