- Home

- Products

- Pouch Packaging Machinery

- Rotary Vacuum Premade Pouch Packaging Machine

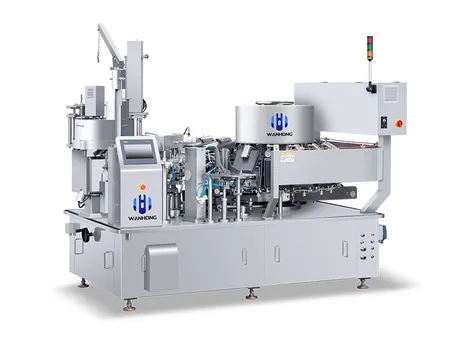

Automatic Rotary Vacuum Premade Pouch Packaging Machine

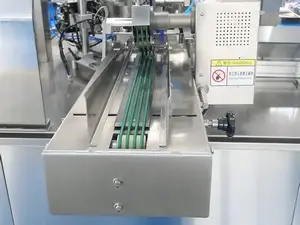

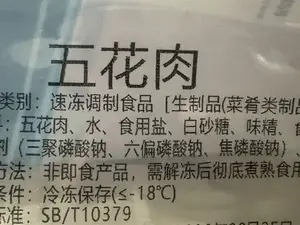

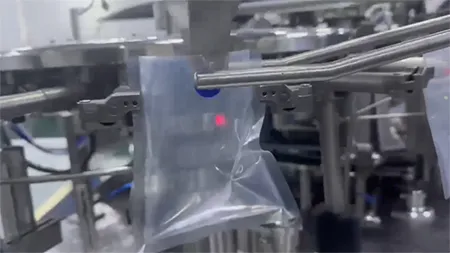

The rotary vacuum premade pouch packing machine is fully washdown-ready with an integrated water tank, making maintenance easy. The design is available in either a mirror or brushed finish. It can handle bag widths from 55mm to 120mm, and the filler is customizable. This vacuum premade pouch packing machine is ideal for packing various materials such as powders, granules, and liquids (at room temperature) into vacuum-sealed pouches.

This vacuum premade pouch packing machine offers a significant increase in capacity compared to traditional single-chamber vacuum packing machines, thanks to the application of up to 16 vacuum chambers. This results in continuous vacuum packing, reducing labor costs and improving efficiency.

- Bag width

up to 300mm

- Packaging speed

up to 100 bags per minute