Our customer, a pharmaceutical company based in the United States, decided to upgrade its packaging line to full automation in response to rising production demand. The product consists of a resealable zipper bag containing 50 small sachets, each individually packed with a single tablet. Previously, the line operated semi-automatically - tablets were filled into sachets by an automatic machine, while the task of placing 50 sachets into each zipper bag was performed manually. Since manual packing was slow, labor-intensive, and unable to keep pace with growing orders, the client partnered with Wanhong to develop a customized automated packaging solution.

During the design and implementation of this automated packaging lines, our team tackled several challenges:- The customer required full automation, connecting the zipper pouch packing line with the upstream labelling system and the downstream inspection lines.

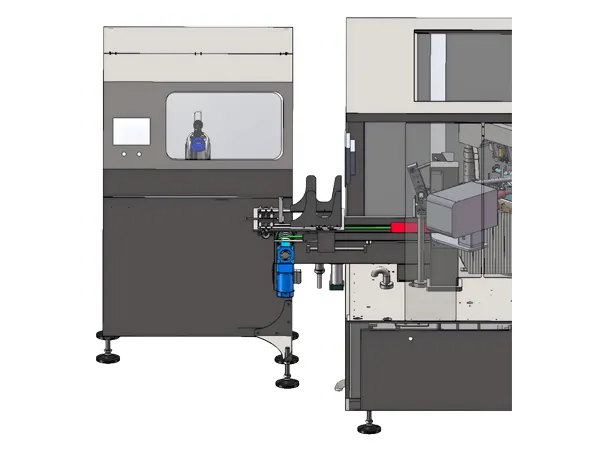

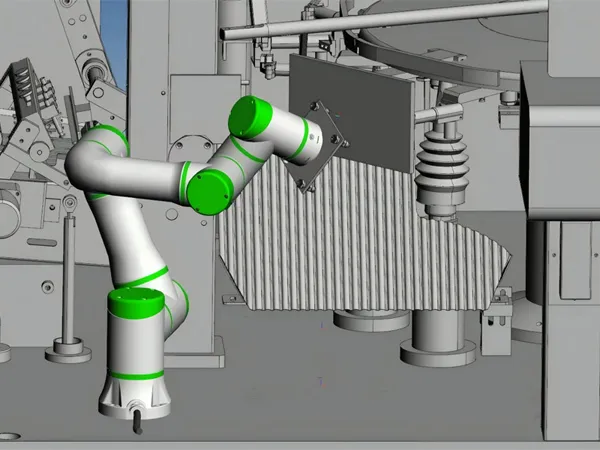

Our solution: We integrated high performance robotic arms at both the bag feeding and the sachet’s output station to ensure seamless connection. - The zipper pouches had limited capacity, and the 50 small sachets occupied a considerable space. However, high-speed packing might lead the sachets to jam at the bag opening, preventing proper sealing.

Our solution: We added multiple pushing mechanisms after product loading. The pushing heads were custom-designed to press the sachets down completely while retracting smoothly without pulling any sachets back up. - The customer demanded a 100% qualification rate, including seal integrity, correct quantity, and detection of empty or defective sachets.

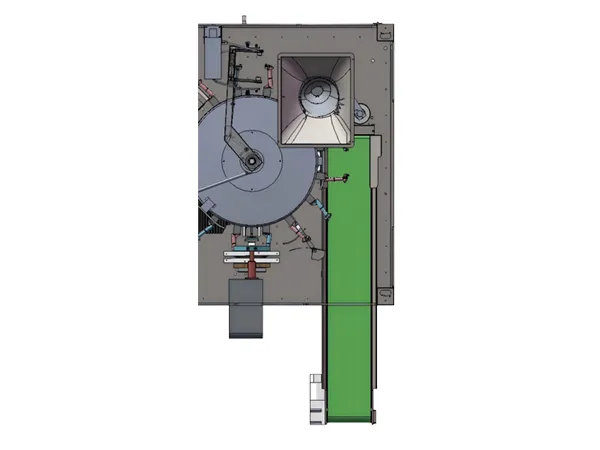

Our solution: In addition to multiple devices that improve packing accuracy, we added inspection units at the sealing stages. Moreover, we installed a rejection conveyor before the final output belt, ensuring only fully qualified products leave the line.

Robotic arm at the bag loading station

Robotic arm at the bag loading station Robotic arm at the output station

Robotic arm at the output station Rejection conveyor (for unqualified products)

Rejection conveyor (for unqualified products)In the end, we successfully overcame all the technical challenges and delivered a smooth, high-speed, and fully automated packaging line that met the customer’s high-performance standards.